High-Density Polyurethane Foams Have Been Around A Long Time

Contrary to many peoples beliefs, the method of raising sunken concrete with polyurethane is not a new technique. Regardless of the terminology used: “Polyjacking”, “Foamjacking”, or “Polyurethane Concrete Raising”, it’s been in use since the 1980’s. In fact, the method of raising and supporting concrete with foam was developed for road repair projects and later patented. Since the expiration of the original patent, several companies have created various formulations of concrete lifting foam. For commercial, residential and municipal applications, we now have access to polyurethanes designed to deal specifically with difficult problems mudjacking never could.

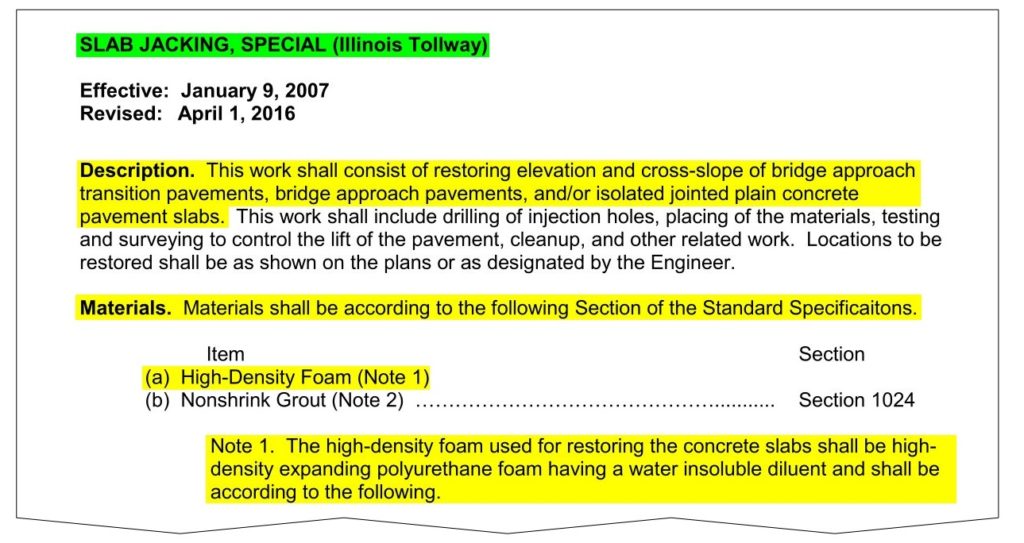

Polyurethane Is Chosen Material For Slabjacking The Illinois Tollway

Acme Concrete chooses to deal in facts. We may have opinions on certain matters, but we will never state something to be fact unless it truly is. We hear a lot of talk out there – mostly originating from mudjacking companies – saying polyurethane doesn’t work. One of our responses to that is to direct people to the fact that the Illinois Tollway solicits bids for raising highways specifically requiring the use of polyurethane. Below are some highlighted portions of an Illinois Tollway bid specification that was released to contractors in 2018.

The engineers who write bid specifications such as this one are educated, unbiased professionals. Time and time again, polyurethane is the material required to restore the elevation of our busy highways – not mud or concrete/aggregate based slurries. These decisions are not limited to Illinois – State Departments of Transportation all across the United States have specifications written similar to this.

Polyurethane Does What Mudjacking Never Will

Unlike mudjacking slurries, polyurethane is injected beneath the settled concrete as a thin, non-viscous liquid. These properties allow the polyurethane to travel more freely; spreading out far away from the injection point. A reaction then takes place, causing the polyurethane to expand 10-20 times its original volume. As the foam expands, voids are filled and pressure is exerted between the concrete and the sub-base. As the sub-base achieves the necessary compaction level, the force of the expanding foam then results in raising the slab above. The foam fully cures in about 15-minutes providing for nearly immediate reuse of the lifted areas.

We’re Geared For State Highway Projects

If you’re a contractor looking for a company to perform polyurethane injections for your highway contract – Acme Concrete is an easy choice. We have polyurethane to meet any specification, and all the equipment and people to successfully execute the project.