Have you read or been told polyurethane concrete raising is dangerous or somehow unsafe? If you have, chances are it’s coming from a mudjacker. Mudjackers cannot compete economically, performance wise or in terms of longevity when it comes to polyurethane concrete raising.

Since mudjackers can’t compete with the superiority of polyurethane concrete raising, some will do what they can to get business – they resort to scare tactics. A lot of consumers see right thru these falsehoods.

Fun Foam Fact: Not all mudjacking contractors are “stuck in the mud”! Here are a few companies that now offer Polyurethane Concrete Raising:

Polyurethane is obviously all around us. It is a common, household material and can be found in almost every home or business – including the mudjackers home or place of business! Polyurethane is in mattresses we sleep on, clothing we wear, furniture we sit on, and even in certain medical devices.

Don’t be swayed by a mudjacker who slanders poly. It’s important to remember that a mudjacker’s #1 competitor is a contractor who raises concrete with polyurethane.

Lifting concrete with polyurethane is like comparing your smartphone to a rotary phone from the 70’s. Both devices provide a service, however, one does it way more efficiently. The polyurethane technique is a far more superior product and process.

Polyurethane is specifically engineered to raise concrete. Made from recycled materials, polyurethane is so strong its weight-bearing capabilities will support a Sherman tank! Poly doesn’t crack, break down, or fall apart like mudjacking material. Even better, it’s a clean & neat process unlike old messy mudjack methods. Polyurethane technology is sophisticated – just like a smartphone. When comparing polyurethane vs mudjacking we can conclude that polyurethane foam is superior to mudjacking in every way!

The Art of Polyurethane Concrete Raising

Although more and more mudjackers have joined the industry and have now added polyjacking services to their business, some still remain ‘stuck in the mud’. Those contractors aren’t willing to designate the required time necessary to properly learn the polyjacking technique. They may also be unwilling to make the financial investment required. The polyurethane technology is far superior to that of mudjacking. It’s technical and requires careful maintenance, unlike mudjacking which is just basically pumping sloppy slurry through a loose fitting pipe. Concrete raising with polyurethane is a specialized art. It takes time and training. It is our belief that mudjackers hesitate to offer poly due to the financial investment and time required to properly learn the trade. We do not believe their reluctance has anything at all to do with health, safety, or the environment.

Why Mudjackers keep Mudjacking

It can be human nature to want to stay in your comfort zone and simply stick with what’s familiar. However, when a company that raises concrete slanders the most technically advanced method available, we have to ask ourselves why.

Mudjacking slurries vary from contractor to contractor. They’re typically made from clay, sand, crushed limestone and on occasion, perhaps cement. The point being that these components are relatively cheap. Although we regularly underbid mudjacking quotes, the polyurethane product we use costs more than mudjacking material. In short – mudjackers reap huge profits by charging rates comparable to our polyjacking services all the while enjoying very low material costs. Simply put, a mudjacker may have to sacrifice profits in order to offer polyurethane concrete raising at comparable prices.

Freaky Fact: The mudjacking process involves drilling large holes in concrete. Once the hole is drilled, a loose fitting pipe is then inserted in order for the slurry to be pumped under the slab. Can you believe the only thing holding the pipe in place is the mudjacker’s boot?

Compared to mudjacking, there is a significant financial investment required for obtaining specialized polyjacking equipment. On the other hand, a mudjacking setup is quite rudimentary, all it has to do is mix and pump a simple slurry. Polyurethane injection systems, however, are comprised of several electro-mechanical components most mudjackers are likely unfamiliar with.

Another reason a mudjacker might hesitate to offer poly is the need for extensive employee training that enable crews to properly install polyurethane. No one is a polyurethane injection expert from the start – it’s a skill that takes time and experience to learn. Correct installation techniques are critical to conducting a safe and successful polyjacking project. With polyurethane, we don’t just step on a pipe stuffed in hole with our boot to inject a sloppy material!

The real truth of the matter is this: The polyurethane material and injection service that we provide requires a significant investment of both time and money. Many mudjacking companies are unwilling to make these sacrifices.

Fun Foam Fact: Large Highway and Tollway project specifications require the use of polyurethane foam! These projects will not accept any type of mudjacking bids – with or without cement.

Concrete Raising "Fake News"

Educated mudjacking contractors know they can’t compete with the superior polyurethane product. Unfortunately, some of these contractors resort to deceptive, unscrupulous marketing campaigns. They use SCARE TACTICS to sway uninformed consumers into using a lesser, older technological solution. Certain contractors twist, or exacerbate health and/or environmental fears simply to gain business. They don’t provide certain relevant facts or present information in its proper perspective – both of which are critical to making an informed decision. Some contractors also claim to use “Natural Materials”, while failing to mention that “natural” is not synonymous with “safe”. Unfortunately, by illuminating only certain aspects of a much bigger picture, they leave consumers with a lopsided, biased view.

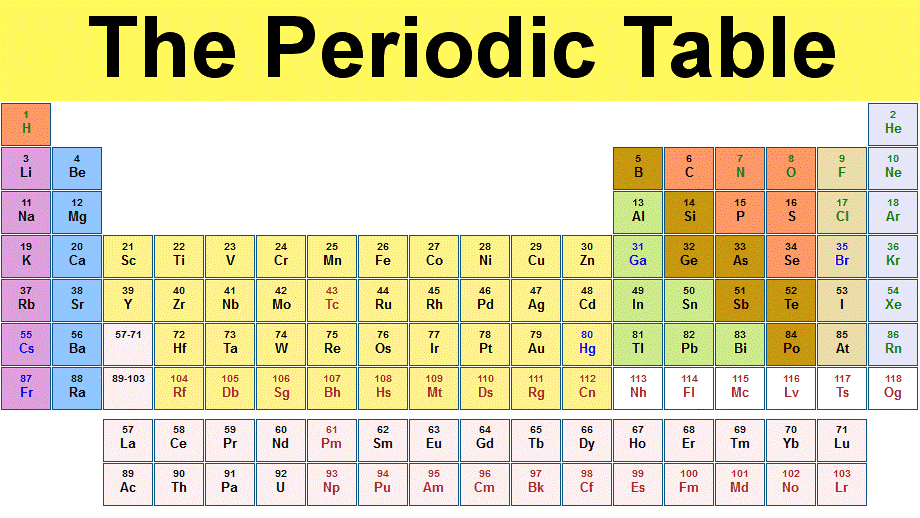

Freaky Fact: The Periodic Table contains 118 naturally occurring chemical elements. Many of these are fatal even in cases of limited exposure! The nasty ones include: plutonium, arsenic, cesium, fluorine and beryllium.

10 Most Dangerous Elements

https://www.planetdeadly.com/nature/10-dangerous-chemical-elements

We are exposed to potentially dangerous hazards every day. Some of these hazards naturally occur in our environment. Chemical compounds (for example: polyester) make up much of our modern way of living. When used as intended, these products present little harm to a consumer. After all, consumers don’t eat asphalt driveways or stick their heads into an operating microwave. Some things are just common sense.

Asphalt roadways and gasoline are common items people use daily. Both of these products contain benzene – which is a known carcinogen. These products only become hazardous when personal exposure to a dangerous compound exceeds a safe amount. Unsafe exposures typically takes place when safety precautions, guidelines and/or instructions are not known and/or followed. Unsafe exposures can occur as the result of an accident or negligence.

Mudjackers who claim to create a “cement mixture” to raise concrete are most likely placing their employees AND customers in direct contact with a known human lung carcinogen: Respirable Crystalline Silica Dust! (Mudjackers probably leave this information out when discussing their product.).

When thinking about potential hazards, it is important to keep things in perspective. Mudjackers who mix cement can reduce carcinogen exposure (silica dust) by supplying respirators to employees. Exposure to potentially hazardous substances is manageable as long as proper safety guidelines are followed. After all, millions of people receive medical tests such as x-rays, MRI’s, and scans which are all performed by employees who follow guidelines.

Fun Foam Fact: Acme Concrete Raising & Repair developed the Smart Lift System and is Chicagoland’s very first concrete raising contractor to focus primarily on Polyurethane Concrete Raising & Stabilization technology!

Most of us own and use a microwave oven on a daily basis. These handy devices heat food and beverages quickly and efficiently. But how do they work? Common household ovens are equipped with a magnetron which produces electromagnetic radiation. This radiation is emitted within the confines of our home. It’s a well-known fact that radiation can be harmful. However, most of us are able to safely rely on potentially harmful devices by simply following the safety instructions.

Microwave ovens are specifically designed to limit radiation exposure. Here again, we don’t stick our head in the oven when operating it. We follow the safety guidelines and use the product as it is intended. With regard to microwave safety, the FDA sets and enforces standards of performance for electronic products to ensure radiation emissions don’t pose a hazard to public health. For more about microwave ovens…

Freaky Fact: A large exposure to radiation may be harmful or fatal. But even under normal circumstances, we’re all a little bit radioactive!

Are Our Bodies Radioactive?

We’ve also seen contractors incorrectly compare the installation of spray foam insulation to polyurethane concrete raising. Although the materials used are similar, their application process is COMPLETELY DIFFERENT. Potential health hazards associated with spray foam insulation do NOT apply to polyurethane concrete raising. While both services use a polyurethane foam, their similarity ends there.

Applying spray foam insulation involves combining two materials commonly referred to as ”Side A” and “Side B”. Side A is made up of isocyanate and Side B a Polyether Polyol Resin. Combining the two materials to produce a polyurethane foam is the only commonality between spray foam insulation and concrete raising foam. Their application process is totally different.

During the application of spray foam insulation, the insulation spray gun will hydraulically atomize or “spray” the mixture upon exit. The resulting combination of materials A & B travel through the air and onto the surface requiring insulation. The chemical reaction of combining “Side A” and “Side B” takes place in open air – meaning within the airspace shared by the installer.

This scenario is somewhat similar to auto body repair work where chemicals are sprayed within the breathing space of the applying technician. These well-known potential hazards are routinely managed proactively and in accordance with OSHA standards. Engineering controls such as fans and ventilation systems are typically utilized in conjunction with personal protective equipment such as respirators, gloves and Tyvek suits.

The application process for Polyurethane Concrete Raising is completely different from that of insulation spray foam. A spray foam insulation process uses a spray gun typically for indoor applications whereas concrete raising uses a specialized injection gun and injection port typically for outdoor projects. These application tools and scenarios are very different.

During concrete raising, when the A & B materials combine, they exit the injection gun as a liquid – NOT as a spray emitted into the air. This liquid does not come in contact with an installer’s air space. It travels through a tightly sealed connection and is applied directly beneath the concrete slab requiring raising. The process of raising concrete with polyurethane does not result in the potential for personal exposure as found with the application of spray foam insulation.

Is Polyurethane Foam Hazardous?

”A mudjacker told me if I raise my concrete with polyurethane, I can’t dispose of it.”

Polyurethane foam is not hazardous. Even mudjacking contractors utilize polyurethane to repair foundation cracks inside customer’s homes. Polyurethane is also routinely utilized for environmental applications. However, in the rare case where disposal of polyurethane is required, rest assured that it can be disposed of in a municipal landfill. We’ve had direct communication with the Illinois Environmental Protection Agency to confirm this fact.

Many sources have documented facts stating polyurethane foam is non-hazardous. Safety Data Sheets from the manufacturer indicate cured polyurethane foam is not listed as carcinogenic per NTA, IARC, and OSHA, and is not classified hazardous per OSHA 29 CFR 1910.1200.

What About Concrete Raising Raw Materials?

Contractors who raising concrete do so by using a mixture of materials. The materials used by mudjackers can vary from contractor to contractor, as well as from job to job. A polyurethane contractor uses a durable foam product that is consistent on every job. Mudjackers use a variety of agricultural products to form a slurry. Polyjackers utilize an engineered product that’s manufactured to exacting standards. One relies on quality control standards, the other typically does not. However, both methods can involve the use of potentially dangerous materials if not handled properly.

Some mudjackers claim to provide customers with a cement-like mixture. It’s possible these mixing operations can result in personal exposure to crystalline silica dust (carcinogen).

While silica may be one of the most abundant elements in soils, crystalline silica dust is a known human lung carcinogen. Crystalline silica is a toxic, carcinogenic and very dangerous chemical. Occupational exposure results in diseases such as silicosis, lung, bronchial, throat and stomach cancers, chronic pulmonary effects, autoimmune and kidney complications.

Freaky Fact: One of our most abundant resources, Crystalline Silica Dust is known to cause lung cancer.

Learn More About the dangers of Crystalline Silica Dust

Concrete Manufacturing

While mudjacking may involve the use of a known human lung carcinogen, polyurethane foam production isn’t completely hazard-free. Polyurethane foam production includes the use of isocyanates which, by themselves, are classified as a potential human carcinogen. However, isocyanates do not come in contact with your concrete, or the soils beneath your concrete.

Before any material exits our equipment, the isocyanate is combined with a non-hazardous material called polyether polyol resin. Once all the “ingredients” are combined in a very safe, controlled way, the resulting product installed beneath your concrete is a closed-cell foam that is:

- chemically inert

- non-leaching

- not listed as carcinogenic

- and not classified as hazardous per OSHA regulations.

How Do We Really Know Polyurethane Is Really Safe?

If someone is trying to convince you polyurethane is unsafe, try to remember that “talk is cheap” and “don’t believe everything you hear”. The best thing to do is to research facts and keep things in perspective.

Polyurethane concrete lifting foams have been subjected to extensive analytical testing to prove they’re a safe, environmentally friendly, concrete raising material.

Fun Foam Fact: Millions of people (and pets) enjoy the comfort and durability of mattresses made of polyurethane foam. Yes, even the mudjackers who say it’s unsafe likely sleep on polyurethane!

For you technically minded consumers, one of the testing protocols used to determine this was EPA’s SW846, “Test Methods for Evaluating Solid Waste, Physical/Chemical Methods”, in accordance with the Resource Conservation and Recovery Act (RCRA). This strict testing procedure and protocol was selected for testing to represent a simulated landfill environment – the worst possible conditions the foam would encounter in any typical geotechnical application.

Of the analytes tested in which the EPA has set a regulatory concentration level, none were of detectable concentration. This not only verifies that cured foam is a non-hazardous material, but it is an environmentally safe choice to use when water is present.

Polyurethane Works To Help Our Environment

Polyurethane is one of the most versatile products in the world. Not only is it the best material to lift and support sunken concrete, it’s used in countless ways to better our lives as well as help our environment.

Polyurethane foam has been used as an encapsulant and proven to effectively contain chemical/biological attack simulants. Testing has found polyurethane to prevent these harmful substances from leaching when disposed of – therefore allowing the safe handling and long term management of an otherwise hazardous material.

polyurethane is also used to adsorb petroleum hydrocarbons from oil spills. Argonne National Laboratory created a polyurethane sponge that absorbs up to 90 times its weight in oil. This method of remediation minimizes the environmental impact of spills; saving time and money by providing a quick, simple solution to highly contaminated areas. Once the contaminants are collected, they can be extracted from the polyurethane for recycling or disposal.

Because of the inherent resistance to water, BASF used polyurethane to develop products that solve modern problems for storm water runoff and coastal erosion. FilterPave® allows rainwater to drain through walkways and flow directly into the ground instead of becoming runoff which can pick up pollutants (like pesticides) or add to flooding. Elastocoast® is used to protect coastlines by absorbing wave impact and reducing wave run-up. This product has also enabled algae and other plant life to sustain which in turn supports animals living along the coast.

About Acme Concrete Raising & Repair

Acme Concrete Raising & Repair is the first concrete raising contractor in the Chicagoland area to specialize primarily in polyurethane injection technology. We developed the Smart Lift System and have multiple polyurethane injection units ready to serve residential, commercial as well as municipal customers. Most of our polyurethane competitors are companies built upon other primary services such as waterproofing, concrete installation or mudjacking. Polyurethane injection technology is, and has always been our primary focus. We’ve invested the time and resources necessary to obtain the most advanced equipment and highest quality material currently available. More importantly, our employees are extensively trained and certified in the proper installation of polyurethane lifting and stabilizing foams.

Some More Information About "Mudjacking"

What does “mudjack” mean?

The term “mudjack” refers to an old method used to lift sunken concrete slabs. Mudjacking has been in use for over 70 years and involves pumping a slurry mixture of sand, cement, and/or soil below a concrete slab through surface holes. The hydraulic pressure from the mudjacking machine causes the slab to rise back into place. This process is called mudjacking because the material pumped beneath the concrete resembles mud, and in many cases it is actual mud since these contractors don’t want the hassle associated with having to clean cement out of their equipment.

Is mudjacking a good idea?

While silica may be one of the most abundant elements in soils, crystalline silica dust is a known human lung carcinogen. Crystalline silica is a toxic, carcinogenic, and very dangerous chemical. Occupational exposure results in diseases such as silicosis, lung, bronchial, throat, and stomach cancers, chronic pulmonary effects, autoimmune, and kidney complications. One of our most abundant resources, Crystalline Silica Dust is known to cause lung cancer. If someone is trying to convince you polyurethane is unsafe, try to remember that ‘talk is cheap’ and ‘don’t believe everything you hear’. The best thing to do is to research facts and keep things in perspective. Mudjacking can lift sunken concrete and help extend the life of the slab, offering a cost-effective alternative to full replacement. However, it’s important to be aware of potential issues associated with the repair process. Property owners should consider the three main challenges of mudjacking before deciding on a repair solution. Additionally, the use of polyurethane foam is now recognized as the preferred method for lifting concrete due to its effectiveness and benefits