Before deciding on how you want your concrete raised, it will be important to understand the major differences between the methods currently available. The method you choose to fix your sunken concrete will have a big effect on how your concrete will look and how long it will stay raised. The equipment, lifting materials, and expertise of a contractor will determine these important differences. The goal of this article is to inform you so you can avoid making the most common mistakes when selecting a contractor to lift your concrete.

VIDEO: ACME VS Mudjacking

Understanding Concrete Raising: Polyurethane vs Mudjacking

When looking into concrete raising service providers, you might find both polyurethane and mudjacking being offered. Either method will require injection holes to be drilled into the slab and either method will raise the concrete; however, that’s where their similarity ends! Comparing poly to mud is like comparing a Tesla to a horse and buggy. Both do a similar job, but one has major advantages.

Mudjacking

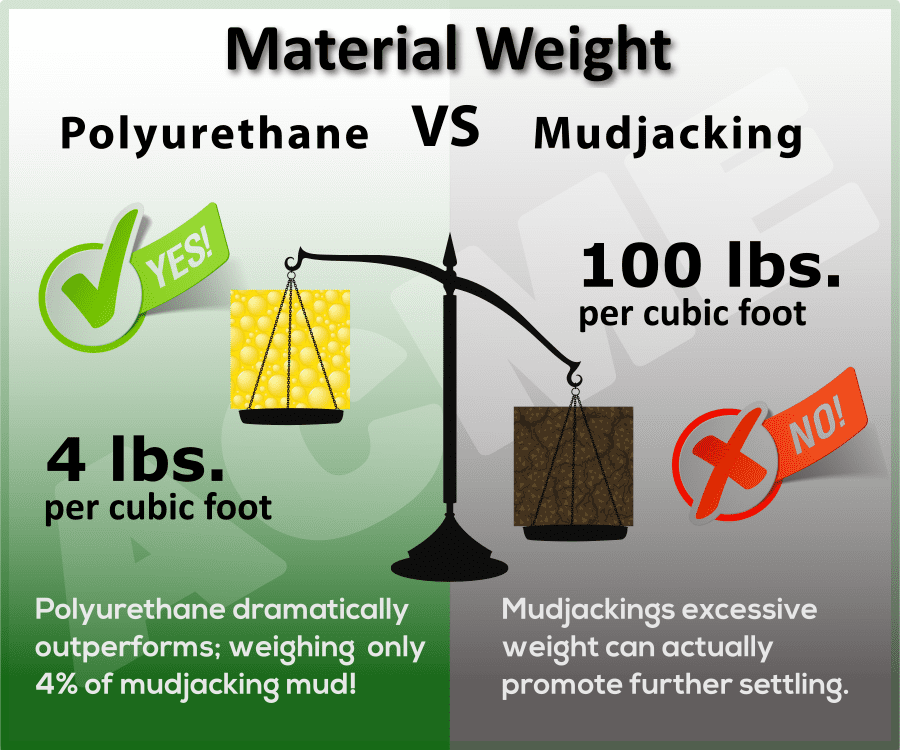

Mudjacking is a well-known term simply because it’s been around for a long time. This longevity is primarily due to the industries lack of a better way to lift settled concrete. In short, there are a lot of disadvantages to mudjacking. Mudjacking material is the result of mixing a heavy, water-based slurry weighing more than 100 pounds per cubic foot. These mixtures usually include soil or clay, possibly sand, and a small amount of cement. The physical properties of mudjacking material will vary greatly from one contractor to the next, and there are no guarantees as to how well it will resist erosion. If you compare one mudjacker to another, it’s difficult to understand the differences between their mixtures; however, any mudjacking material will add significant weight to an already problematic area. These water-based slurries are very thick and require large holes to be drilled into your concrete. Typically, several 1-⅝ inch-diameter holes are used, which are then patched after the slab is raised.

Polyurethane

Polyurethane foam concrete raising was developed to provide a better solution to settled concrete. Originally limited to large infrastructure projects, this advanced process is now widely available for commercial and residential applications. Various polyurethane materials continue to be developed to address a wide variety of problems that mudjacking could never solve. Like mudjacking, polyurethane does require holes to be drilled through the slab; however, these holes are much smaller, only 5/8 of an inch in diameter. Once patched, they’re hardly noticeable. Polyurethane equipment also provides the ability to access heavily landscaped areas with only a small hose, whereas mudjacking typically requires large, heavy equipment within 10–20 feet of the work area. Polyurethane is not subject to erosion, cures in about 15 to 30 minutes, and can provide a compressive strength suitable for stabilizing large highway slabs.

- Engineered to exact specifications

- Very light material

- Small injection holes

- Cured in 15-30 minutes

- Will not wash out

- Long term warranties

- Mixtures vary widely

- Very heavy material

- Large injection holes

- 1 to 2 days to dry

- Susceptible to erosion

- Short term warranty

If you are in the Chicago area and are in need of sidewalk lifting, garage floor leveling, or a concrete patio repair, don’t hesitate to reach out to the concrete raising experts at Acme today for a FREE quote.

Benefits of Using Polyurethane vs. Mudjacking

There are two very important differences in appearance when it comes to using poly foam vs. mudjacking. For both methods, holes will have to be drilled into the concrete to inject the material underneath the concrete slab to lift and raise it from the settled ground beneath it. However, the two injection materials are very different from one another. When it comes to a polyurethane foam injection, the material and equipment allow for much smaller 5/8” holes (the size of a dime) to be drilled for a minimally invasive approach. For mudjacking, the holes required are much larger, around 1 5/8” inches. The mudjacking mixture being injected is much thicker than polyurethane, so even more holes have to be drilled. Not only are the holes larger, the quantity of holes increases as well.

Mudjacking uses an extremely heavy material made primarily of sand, clay, and water to lift concrete. This material can weigh upwards of 100 pounds per cubic foot. The addition of this material to an already unstable ground beneath the concrete only adds more stress to the site – almost guaranteeing that the ground will settle and sink again. On the other hand, commercial grade polyurethane foam only weighs 4 pounds per cubic foot. The lightweight material is stronger and puts way less of a strain on the ground below, which drastically reduces the chances that the ground will settle again in the future. The poly foam will certainly outlast the mudjacking repair.

Erosion resistance has everything to due with the longevity of a repair. The polyurethane foam we use is completely erosion resistant. Remember, erosion is one of the primary reasons why concrete sinks. Poly foam is a high-density, environmentally-friendly foam that turns into a solid material within minutes after injection, and will keep its shape over time without any shrinking. The mudjacking grout on the other hand is just sand, clay or limestone and perhaps cement mixed with water which means it is highly susceptible to erosion and stands the chance of being washed away from water and moisture over time. This is another great reason why polyurethane foam can stand the test of time over mudjacking.

When it comes to poly foam for lifting settled concrete, the process is much cleaner and more efficient. Our poly foam equipment comes self-contained in a small box truck or pick up and small trailer. No heavy construction equipment required! The polyurethane material comes ready to use on demand – unlike the mudjacking process which requires much more extensive and invasive equipment. On top of that, the polyurethane method is much faster than mudjacking. Once the material is injected, a car can drive over the repair in just 15 minutes, unlike mudjacking where you are left to wait for the material to solidify 1 to 2 days before the concrete can be used. This is especially convenient for businesses since employees or customers can use the area immediately after we leave a job site. Our Smart Lift System keeps everything contained throughout the process, making clean up a breeze so our team will be out of your way in no time at all.

On top of all these benefits polyurethane is also typically competitive with or cheaper than mudjacking. Not only are you getting a more durable, longer lasting, minimally invasive, and faster concrete repair, you’re also getting an economically smart repair when you have Acme lift your settled concrete.

Watch Polyurethane vs Mudjacking in Action

The pros greatly out way the cons when it comes to polyurethane concrete raising vs mudjacking. But don’t just take our word for it. View our 4-part video series below for an in-depth look at how polyurethane is faster, cleaner, more durable, and far longer lasting than mudjacking. Then reach out to our team for a quote on your job and we’d be happy to answer any questions you may still have!

1. Lifting Materials: ACME VS Mudjacking

Concrete raising repairs are only as good as the materials used to lift your concrete. Your lifting materials will probably be subjected to water, and sometimes, extreme weight loads. Make sure you’re getting materials that will stand up to Chicagoland’s punishing weather!

2. Repair Aesthetics: ACME VS Mudjacking

Some concrete raising services will permanently deface your concrete, leaving it looking scarred for life. When you have your concrete raised, make sure you understand exactly how invasive the process will be.

3. Warranty: ACME VS Mudjacking

Sometimes a warranty will sound better than it actually is. Make sure you always read the fine print before making a decision. The details of a warranty are an indicator of a contractor’s confidence in their own work. You should get a solid warranty without tricky loop-holes.

4. Cost: ACME VS Mudjacking

Mudjacking is overpriced for what it is you’re getting. To complicate matters further, some multi-service companies bid polyurethane jobs at rates exceeding the cost to replace your concrete. Before hiring a contractor, be sure you fully understand the products and services being offered.

Polyurethane Foam vs Mudjacking Comparison

| Characteristic | Polyurethane Foam Injection | Mudjacking |

Material Consistency |

Polyurethane Foam Injection Acme's polyurethane concrete lifting utilizes a two-part polymer, precisely blended with sophisticated equipment. The result is the formation of lifting foam consistent with every project. |

Mudjacking Mudjacking slurries vary from Mudjacker to Mudjacker. Although there may be exceptions, most contractors do not rely on precise measurements when mixing their slurries. |

Injection Hole Size |

Polyurethane Foam Injection Polyurethane uses a very small injection hole size, ⅝” in diameter - about the size of a dime. After patching it is barely noticeable. |

Mudjacking Mudjacking requires much larger holes, typically 1 - 2 inches in diameter. Large holes can weaken the structure and the patches are more noticeable. |

Injection Hole Quantity |

Polyurethane Foam Injection Polyurethane is injected as a thin liquid and travels easily between the slab and subsurface, therefore requiring fewer holes to obtain the required coverage. |

Mudjacking Most mudjacking operations utilize a very viscous or thick mixture that is unable to travel as easily as liquid polyurethane. |

Lifting Material Weight |

Polyurethane Foam Injection Polyurethane is very strong yet weighs only about 2 pounds per cubic foot. Slabs are lifted without adding significant weight to the subbase. |

Mudjacking Mudjacking slurries weigh about 100 pounds per cubic foot. (Remember, weight contributed to the concrete settling in the first place.) The more weight that is added, the greater chance additional settling can occur. |

Repair Time |

Polyurethane Foam Injection Acme's polyurethane is ready to inject on-demand. Also, with fewer injection points, repairs are completed quickly. This process creates no mess, so clean-up time is virtually non-existent.Our polyurethane is cured after about 15 minutes. All lifted structures are ready for use once our work is complete. |

Mudjacking Mudjacking “mud” is made on location by combining water with a dry mixture to form a slurry that is transferred to an injection site. After project completion, the repaired slab and mudjacking equipment often require clean-up, most times on site.Mudjacking mud (slurry) typically requires 1-2 days to dry well enough to withstand any considerable weight. |

Water Resistance |

Polyurethane Foam Injection Polyurethane foam is an inert substance that is resistant to water and will not wash out. |

Mudjacking Depending on material types and mixtures, some mudjacking slurries are more susceptible to erosion than others. In general, mudjacking slurries are more vulnerable to washout than polyurethane. |

Warranty |

Polyurethane Foam Injection Polyurethane provides a long lasting, high-quality repair. We provide a no nonsense warranty without tricky loopholes. Feel free to contact us to learn more. |

Mudjacking Many competitor warranties contain fine print that eliminates any real worth to consumers. |

Who provides polyjacking near me?

Looking for polyjacking services near you? Look no further than Acme Concrete Raising & Repair. Serving the Greater Chicago area for over a decade, we specialize in lifting and leveling sunken concrete slabs, patios, driveways, and more. Contact us now for a complimentary estimate and inspection.

Frequently Asked Questions

- Polyjacking foam is hydrophobic, so if water drains under the slab, the foam won’t move or dissolve.

- Polyjacking foam is inert and non-toxic. The foam won’t move or leach chemicals into the soil or grass.

- Polyjacking foam only weighs about 4 pounds per cubic foot, which means it won’t contribute to further settlement.

- Polyjacking doesn’t require any heavy excavation, trenching, or digging.

- Polyjacked concrete can be used just 15 minutes after the foam is injected under the slab.

- Mudjacking does not last as long as polyjacking because once the polyurethane foam is injected under the concrete, it hardens within 15 minutes, making the slab almost immediately usable. In contrast, mudjacked concrete needs at least 24 hours to become usable again and is susceptible to failure from moisture intrusion. This shorter lifespan and the need for frequent repetition make mudjacking less durable compared to polyjacking, which can last indefinitely.

- The slurry used in mudjacking is not waterproof, which can be problematic. If the slurry comes in contact with water, it can wash out from under the slab. Additionally, the weak nature of the slurry makes it susceptible to shrinking and breakdown, further compromising the stability of the repair.

- During the mudjacking process, 1-1/2 to 2-inch holes need to be drilled into the concrete slab to pump the slurry underneath. However, these holes can potentially weaken slabs resulting in cracks or provide pathways for weeds and roots to grow through, which can damage the concrete structure.

- Mudjacking is considered a messy process because it involves pumping hundreds of pounds of slurry underneath the concrete slab. In the event of a leak or accidental spill, it can lead to a significant cleanup process.

- The weight of the mudjacking slurry is a disadvantage because it is much heavier compared to polyurethane foam. While polyurethane foam only weighs about 4 pounds per cubic foot, the mudjacking slurry weighs about 100 pounds per cubic foot. This increased weight can cause the slab to sink again rather than stabilizing the soil and preventing further sinking.

Are You Still On The Fence About Which Method To Choose?

Our favorite customer are those who dig deep into the facts of the concrete raising industry! Fact is, no matter what company you talk to, you’re being marketed to! Our approach is to simply provide facts to help you come to your own conclusions. To learn even more about the differences between poly and mud, check out our in-depth article here: Polyurethane Concrete Foam Raising vs Mudjacking